A major player in the Purified Mineral Water Turnkey Project, GIECL - Gujarat Ion Exchange And Chemicals Ltd is formed by a group of expert specialists in the water treatment field and applies innovations technologies like Advanced Ion Exchange Membrane and Ultra Filtration in its Packaged Drinking Bottling Plants, which help in industrial processing of water, wastewater treatment and purification, and furthermore control pollution.

GIECL is engaged in designing, advancement, and installation of water purification, and Wastewater & Seawater Treatment Projects, utilizing specialized capability that can be followed to the eighties, a long time before even the organization was shaped.

Purified and methodically done treatment of mineral water needs to be packaged in quality bottles. Freshness and purity of mineral water are highly dependent on the Water Bottling Plant of the equivalent.

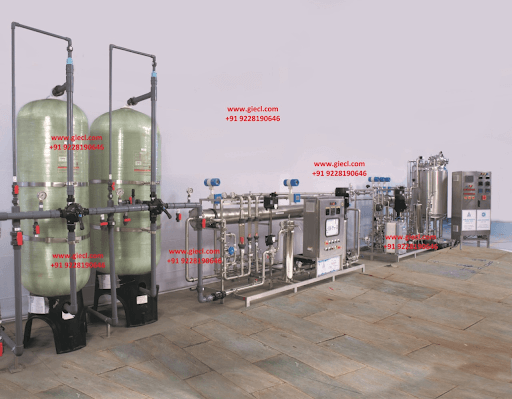

Therefore, the role of the Mineral Water Plant is inevitable for this industry. At Water Bottling Plant/Project India, we emphasize on delivering world-class Mineral Water Plant manufacturing and installation solutions, Our Water Plant include Ultra Pure Water Generation System, Purified Water Generation System, RO Plant, Pharmaceutical RO System, Turnkey Mineral Bottling Water Project, Packaged Drinking Water Plant, Water Filtration Plant, Drinking Water Bottling Plant, etc.

Our services additionally include the supply of spare parts and offering complete maintenance support to the water bottling process. Our expert team sticks to the idea of engineering latest status Ultra Pure Water Generation System for Drinking Water treated with essential minerals.